Bund Linings for Containment in Agriculture & Aquaculture

Bund Lining and Containment in Agriculture

Traditionally Farm Wastes have been mainly stored in unlined pits in the ground, or concrete and steel tanks, which resulted in problems of groundwater and river contamination. Fortunately for most of history, the strength of fertilisers, pesticides and other stored products or waste materials was relatively low and so the outcome in terms of environmental damage and pollution was sometimes significant locally, but overall the ecology of the countryside was not really significantly affected. This was mostly due to the natural filtration in the ground and the natural breakdown of organic compounds by micro-organisms such as bacteria – in a similar way to the aerobic and anaerobic digesters work as outlined on the Sewage & Waste Water Treatment page of this website.

However new environmental regulations and stricter controls have gradually been introduced over recent years with the development of modern methods of farming, monoculture and more widespread used and increasingly concentrated fertilisers and pesticides etc.

The SSAFO Regulations were first made in 1991 in response to a substantial rise in pollution incidents from on-farm silage-making and slurry systems. At one time there were thousands of incidents each year. Happily that number is now substantially down, but there are still many incidents each year, including one or two serious pollutions each week.The SSAFO Regulations set out minimum standards of design and construction, which must be met when silage, slurry or oil storage is used.

Improvement Notices can be served by the Environment Agency when farms are operating without proper storage and creating a significant risk of pollution. The latest update of the regulations was:

The Water Resources (Control of Pollution) (Silage, Slurry and Agricultural Fuel Oil) Regulations 2010 (SSAFO).

These regulations aim to prevent water pollution from stores of silage, slurry and agricultural fuel oil. They set out requirements for the design, construction and maintenance of new, substantially reconstructed or substantially enlarged facilities for storing these substances. The torage facilities should now be sited at least 10 metres from any inland freshwater or coastal water and the structures must have a 20-year life expectancy.

More guidance and helpful information on the requirements are given on the Environment Agency website at: https://www.environment-agency.gov.uk/business/sectors/32755.aspx

New UK Nitrate Pollution Prevention Regulations came also into force in 2009. These are concerned with defined Nitrate Vulnerable Zones (NVZ) around the UK and are designed to minimise the risk of water and environmental pollution from agricultural silage and slurries that are not fully contained, managed or stored properly.

Legislation is also increasing the minimum size and volume of silage and slurry storage required. The new regulations are therefore extensive and every farmer now needs to understand where the NVZ designated areas are, and whether they need to comply with this new NVZ legislation.

In fact from 1st January 2012 all farmers within an NVZ designated area are required to have in place at least 6 months storage capacity for pig slurry and poultry manure and at least 5 months storage capacity for any other livestock slurries such as cattle. Additionally the construction of these storage tanks must comply with the latest Silage, Slurry and Agricultural Fuel Oil Regulations (SSAFO). For those whose land is not in an NVZ, there are still ne wrequirements to provide minimum levels of secure slurry storage in accordance with SSAFO.

Why is this new nitrate legislation there? The nitrates legislation is designed to help reduce the amount of nutrients in rivers, estuaries, lakes and groundwater. Excessive nitrate causes algal blooms in some rivers and coastal waters, harming fishing and biodiversity. There are also strict limits on the amount of nitrate allowed to be in drinking water. Around 60 per cent of the nitrate in surface water (rivers, streams and lakes) in England and Wales comes from agriculture.

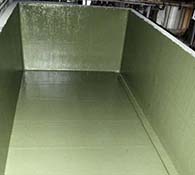

Costs of pollution incidents can easily run into tens of thousands of pounds and this risk can be totally avoided by the use of appropriate storage tanks for primary containment and bunded concrete or masonry structures as secondary containment tanks or areas to hold them. The concrete floor and concrete or block walls must themselves be sealed with a protective coating or lining system that has excellent physical, mechanical, biological and chemical resistance properties. – No problem from the specialists at NCC.

Bund Lining and Containment in Aquaculture

The Food and Agriculture Organization of the United Nations (FAO) says that aquaculture "is understood to mean the farming of aquatic organisms including fish, molluscs, crustaceans and aquatic plants. Farming implies some form of intervention in the rearing process to enhance production, such as regular stocking, feeding, protection from predators, etc.”

NCC work with Off-shore fish farming in providing protective floors, coatings and bund linings for their on-shore fish processing facilities, from the point of landing through preparation and different types of processing, through to packaging and loading for distribution. These areas are normally sealed and protected with chemically resistant epoxy resin or polyurethane modified cement technology based systems to provide a hygienic and safe working environment, whilst protecting the environment by containing potential pollutants such as the processing waste products and cleaning chemicals.

For On-shore fish farms NCC are even more involved as in addition to the fish processing areas, we also provide the resin systems to line and protect the reinforced concrete structures of different hatching and rearing tanks themselves, plus to ensure the watertightness and secondary containment function of the areas in which the tanks are situated. Obviously these tank lining systems are all specially developed and have DWI Approval for contact with potable water. Incidentally these same systems are also used by zoos, theme parks and public aquariums for lining their tanks and any necessary containment areas to prevent any possible pollution of the environment.

Additional Aquaculture Development and Protection of the Environment

Aquaculture or fish-farming has been practised for thousands of years in Asia; it was brought to Europe by the Romans, and became a key activity of Christian Monks with Carp in particular, as part of their staple diet throughout the Middle Ages. This continued in many places in the UK, despite the dissolution of the monasteries, until the middle of 19th Century, when improved transport links meant wild seafish from all around the UK coastline, also became available quickly and at an affordable cost almost everywhere inland as well. Trout farming began at around the same time, primarily on large estates for stocking and restocking lakes and ponds with trout for angling. The first ‘table trout’ farm opened in the 1950.s and this took off in the 1960’s and 70’s and there are now around 200 in the UK.

The industry began to revive around 40 years ago with the first Scottish salmon farms and the majority of UK food ‘finfish’ aquaculture is still Salmon and located in Scotland, but it is increasing in Wales and England. Shellfish culture is spread more evenly throughout the UK. The other main finfish species now being farmed around the UK are trout and halibut, sea bass and turbot, plus there are also now farms raising cod and exotic species such as tilapia, barramundi, catfish and king prawns.

The main shellfish species farmed in the UK are mussels, Pacific oysters, European oysters, King and Queen scallops and clams. These are generally farmed off-shore under nets, on rafts, racks or long-lines and therefore NCC’s involvement in shellfish farming, is in the provision of protective resin coatings and bund linings for their processing facilities on-shore.

Top ten aquaculture producers in 2004 (2008)

| Country | Million tons |

|---|---|

| China | 30.61 |

| India | 2.47 |

| Vietnam | 1.20 |

| Thailand | 1.17 |

| Indonesia | 1.05 |

| Bangladesh | 0.91 |

| Japan | 0.78 |

| Chile | 0.67 |

| Norway | 0.64 (0.87 in 2008) |

| UK | 0.10 (0.16 in 2008) |

| United States | 0.61 |

| Other countries | 5.25 |

| Total | 45.47 m Tons |

In 2006, the Scottish aquaculture industry was estimated to be worth more than £400 million to the economy. The farm-gate value of fish farming in England and Wales was estimated at £23.5 million in 2006. In 2007, shellfish production from aquaculture was estimated at £23 million, most of which came from mussels.

In 2004, the total world production of fisheries was 140 million tons of which aquaculture contributed 45 million tons, about one third. The global growth rate of worldwide aquaculture has been sustained and rapid, averaging about 8 percent per annum for over thirty years, while the take from wild fisheries has been essentially flat or more likely now reducing for the last decade. The United Nations reported that the global aquaculture market reached £55bn ($86 bn) in 2009.

Aquaculture today is clearly continuing to be one of the fastest growing areas of food production in the world and in the UK, where the potential is clearly to more than double or even treble the current levels of farmed fish and shellfish production volumes, as evidenced by the levels in many other countries. The specialist resin coating and bund lining specialists from NCC are ready and available to support aquaculture facility owners, designers and their building contractors, from the design office and right through to successful completion and opening of the new facilities that are going to be required.

The main challenges before the industry today in continuing to rapidly increase production volumes are primarily sustainability of the business and protection of the environment in accordance with all of the latest Environment Agency Prevention of Pollution Guidelines, with which NCC are fully familiar and we are pleased to assist with FREE expert advice wherever we can. For advice in selecting and installing the right tank lining and protective coatings for your specific aquaculture and processing containment areas, please contact any of our offices and one of our specialists will be delighted to assist you.