NCC Bund Lining

Bund Lining Solutions with Independent Expert Advice

Head Office: 01257 266696

Scotland: 01786 472800

Bund Lining

Bund Lining - Home & About Us

Bund Lining Requirements

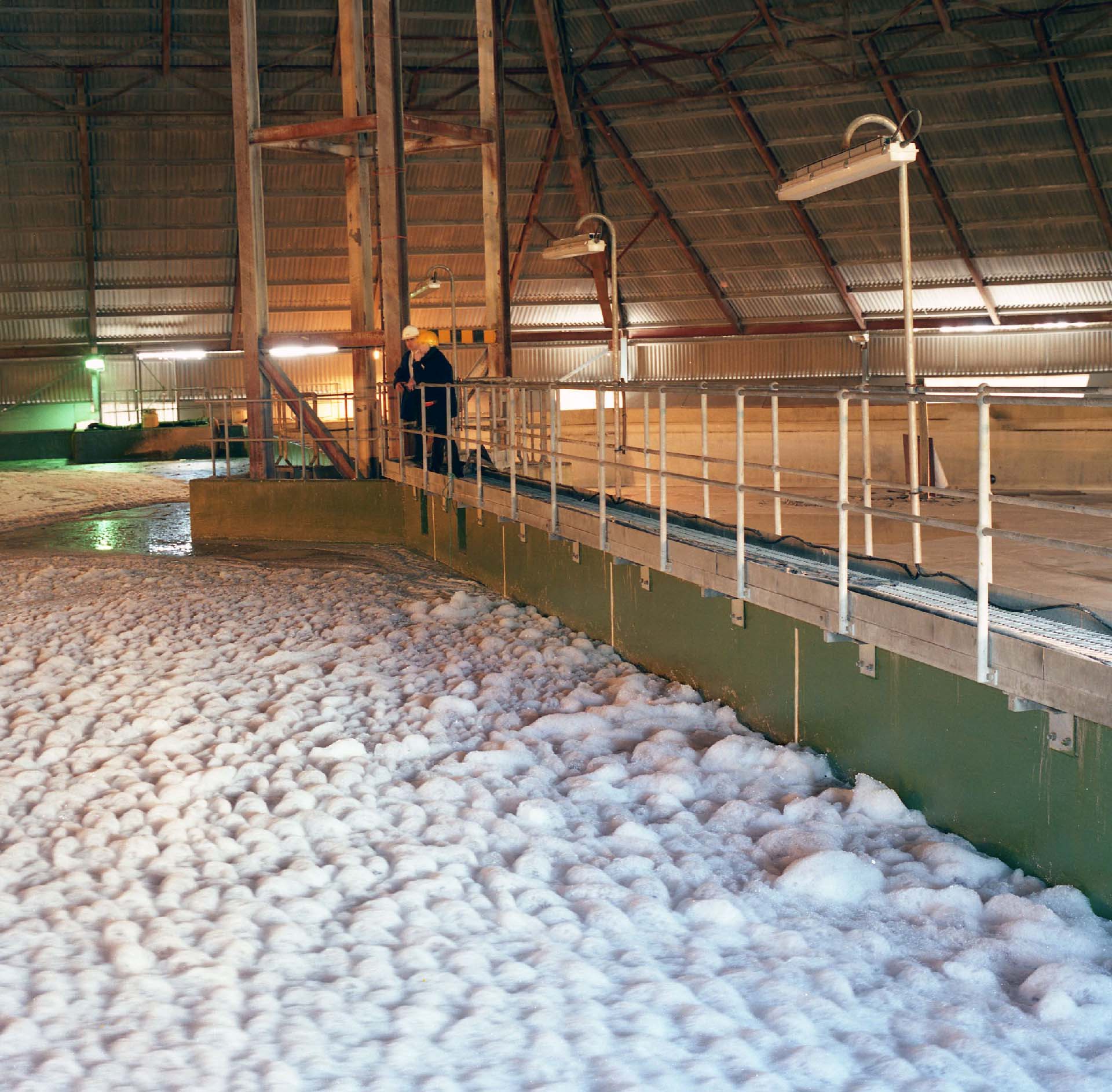

Bund Lining products and bund lining systems come in a wide range of different types of materials and build-ups, together with many different application and performance characteristics. Protective and reliable Bund Lining systems can be required in all types of buildings and other facilities for manydifferent uses. The most common requirements are for the primary and / or secondary containment of oils, waste water and other aggressive chemicals, plus the containment of any potential pollutants for the prevention of environmental contamination or groundwater pollution.

Bunded containment areas are therefore necessary in almost every type of factory production and process facility today; for example right throughout the oil, gas and petrochemical industry and their fuel storage, delivery and sales outlets to the end user’s own storage tanks that must now also be bunded for secondary containment in the event of a spill. Then equally importantly bunded areas are required throughout the power generation and distribution networks; as well as every stage of the waste water and sewage collection and treatment plants; plus there can be many similar requirements in many other areas of all types of industrial, commercial, agricultural and leisure facilities.

In other words, today Bund Lining systems can have almost unlimited uses, demands and applications. Firstly they must provide secure, efficient and cost effective protection against attack and deterioration to the concrete, masonry or steel structures used for the primary andsecondary containment of polluting liquids in order to ensure that the containment structures themselves are able to provide the necessary continuous protection of people and the environment against pollution.Bund Lining systems and protective coating systems for both primary and secondary containment tanks and areas are therefore used to seal, strengthen, protect and enhance the watertightness and chemical resistance properties of the floors and walls of the tank itself, the containment area and the structures this comprises - However – All Bund Lining requirements and all Bund Lining products and systems are definitely NOT the same in nature, function or performance – the right solution must be identified and selected based on the requirements of each project.

Bund LiningTechnologies and Systems

Many bund lining system manufacturers and bund lining contractors have only one type of resin technology, production facility, or application equipment, and therefore they can only recommend and offer you a very biased view on the most appropriate bund lining system materials and system build-up that is best for your project – Especially in the current economic climate, where none of them want to turn any potential work away!

However at NCC we have all of the different manufacturers technologies and systems available, and our Bund Lining advice is totally independent. We have the proven expertise and experience to provide you with FREE expert support and assistance to select the right technology, type and system build-up for the bund linings in all of your containment area projects – Nationwide from domestic fuel oil storage to power stations, aggressive chemical processing areas and all types of commercial and industrial waste water handling facilities – NCC will have the right solution for your bund lining project.

BundLining.co.uk - For Independent Online Bund Lining Information

BundLining.co.uk is a specialist online Bund Lining information and support centre that is completely independent of anysingle Bund Lining technology, bund lining installation method, Bund Lining Manufacturer, Bund Lining Contractor or any other ‘single-concept’ company. BundLining.co.uk has been especialy created and developed by NCC Materials Consultants and Distributors, who are one of the UK’s leading distributor's of specialist chemicals, plus repair and protection products for all types of building and construction works.

NCC has been established with our head office in Chorley for more than 30 years. Today the technical team in our offices and depots around the country have unrivalled expertise with a combined total of more than 120 years’ experience in the UK’s Specialist Bund Lining market.

Bund Lining.co.uk

Was created because we identified a need for an independent specialist support centre for use by Building and Facility Owners, their Site Managers and their Professional Construction and Maintenance teams, including Architects, Consulting Engineers and Surveyors, as well as the Facilities Management Companies and Main Contractors that will usually all need to be involved in thesea projects that frequently involve many disciplines for due care and consideration of any work in these areas.

As the majority of these people are not actively involved every day in bund linings, or primary and secondary containment works, we found that they can all have a need for a reliable source of independent information and advice in relation to all things ‘Bund Lining’ – As a result and after several clinets and customers saying this would be a huge benefit for them and their staff around the country as well as all of their construction preofessionals - So we have created, maintained and continually expanded and developed BundLining.co.uk as a free information and advice site, plus we have our experts available around the UK to provide any additional guidance and assistance from the design office, to the site and in the bund itself on request.

This website therefore contains independent advice and information on the different types of bund lining materials that are available, together with guidance on selecting the right Bund Lining products and system build-up for your projects. This includes a generic overview of each of these different materials and system build-ups, their specific advantages and disadvantages, both in terms of their application and their installed performance and durability in service.

Please browse the pages of our website for information and advice about the different aspects of bund lining for primary and secondary containment protection systems, including the main selection criteria that should be considered, together with the alternative bund lining materials and products that are the most suitable for the specific requirements of your project.

When you need help and assistance with specific advice or guidance for your project – no matter what size, please call any of our offices and one of our Bund Lining specialists will be delighted to assist you.

Repair and Refurbishment of Bunds and Secondary Containment Areas

The repair and protection of bunds and secondary containment areas also has its own specific requirements and procedures, due to the additional difficulties that must be overcome in potentially contaminated and exposed or damaged areas. We have therefore also included guidance and materials selection and advice on the repair and refurbishment of bund areas, including the necessary detailing solutions with the right type of fixings, solutions and systems for sealing around penetrations and across movement and construction joints in the structure. This is provided together with information on the necessary substrate and environmental conditions for execution of the bund repair works, plus the necessary surface preparation and pre-filling of any damage and surface defects such as blowholes etc., to ensure that the subsequent protective bund lining system can form a completely sealed, impervious and resistant barrier to whatever chemical and any other exposure that is to be anticipated.

Please visit our dedicated ‘Bund Repair and Refurbishment’ Page.

The Leading Bund Lining System Manufacturers

At NCC and Bund Lining Site, we only work with the best, world class Bund Lining and containment tank and area protective coating systems manufacturers that have developed thoroughly tested and proven product and systems for these applications using the latest synthetic resin technologies. These leading bund lining manufacturers include:

Akzo Nobel / International Paints and in particular their Ceilcote Specialist Linings Division - are one of the world’s leading manufacturers of the highest performance protective coatings for use as bund linings and both primary and secondary containment vessel and area coatings. Their extensive range for these applications includes materials based on state-of-the-art technology and the highest levels of chemical resistance for durable performance including Phenolic Modified Epoxy Resins for example, as well as urethane, polyester, vinyl ester and other epoxy resin based lining systems.

Sika are now the world’s largest manufacturer of specialist epoxy, polyurethane and polyurea resin based protective coatings and linings together with flooring systems, concrete and masonry repair and strengthening systems. These are ideal for bund repair works prior to application of the new bund linings during refurbishment and upgrading works, plus the Sika CarboDur structural strengthening and Sika waterproofing solutions are renowned and the market and technology leaders for all areas and types of structure – from the basement to the roof as they say!

Sika Cor VE products and systems basd on vinyl ester resins are specially developed for maximum acid resistance and are commonly used in bund lining and protective coating solutions in many manufacturing and aggressive process areas, plus in the water and power industries, especially in cooling towers and other structures exposed to the very aggressive condensates from FGDS (Flue Gas DeSulphurisation).

Sika also produce, high performance and chemically resistant resin adhesives & fixings, including extremely useful elastic adhesive bonding adhesives and joint sealants that can eliminate the need for pentrations through the bund lining system. For example to secure and attach any mechanical equipment or plant that subsequently needs to be installed in the bunded containment area, so that there is no unnecessary damge or penetrations into or through the protective coating system forming the watertight bund and containment structure itself.

ITW Irathane Futura is the Specialist Division of ITW that produces some advanced Polyurethane and Polyurea resin based protective coating products and systems that are used to prevent erosion and corrosion in some of the most aggressive areas of exposure and aggressive environments. Additional advantages of PU and Polyurea technologies is that the majority of these bund lining systems are designed for spray application and in the case of polyurea, to be very fast curing, which means that larger areas and difficult substrates can be more easily accommodated and completed quickly. Polyurea systems also include a range of systems approved for tank and other structural linings in direct contact with potable (drinking) water, as well as others designed specifically for protection against aggressive ground water and/or waste water.

Remmers are manufacturers with a focus on sustainability and constantly look to reducing the environmental impact and footprint of their products and systems, which include epoxy and other resin based protective coatings and chemically resistant materials for flooring and ground water protection, waterproofing and damp-proofing solutions, plus concrete and masonry repairs, specialist stone cleaning andrestoration treatments and probably the world’s best ecologically-friendly protective wood and timber treatments.

VIP GmbH is a German specialist manufacturer of advanced polyurea products together with some equally advanced combinations of Polyurea and PU products and unique, innovative spray equipment for the successful application of these systems in both large and small areas. VIP have focussed their coatings and linings development on the tough demands of the construction works on site in different environmental conditions and have the most practical experience of any manufactuer with these high performace materials in our our experts views.

At NCC Bund Linings our objective and our daily business is the supply of the best and most cost effective materials with FREE Expert advice to provide you with solutions for the technically correct repair and protection of all types of concrete, masonry and steel surfaces exposed to aggressive influences. This includes all of the available materials technologies from cement to resin based repair materials, resin flooring, resin tank linings, resin bund and containment systems, and a wide range of special protective resin coating systems, all specifically selected according to the defined requirements and levels of exposure in your specific project i.e. to abrasion and impact, to chemicals and water, to temperatures and UV light etc. We work closely with all of the major global materials manufacturers outlined here, plus other specialist materials manufacturers for their unique bund lining products and specialist protective coating systems that we can quickly source, when required for our customers different requirements and projects.

When you need help and assistance with specific advice or guidance for your bund lining project – no matter what size, please call any of our offices (Scotland: 01786 472800 and Chorley: 01257 266696) and one of our specialists will be delighted to assist you.

Use Quick Links

- Food & Beverage

- Oil, Gas & Petrochemical

- Chemical Processing

- Agriculture & Aquaculture

- Sewage & Waste Water Treatment

- Power Generation & Transmission

- Nuclear Facilities